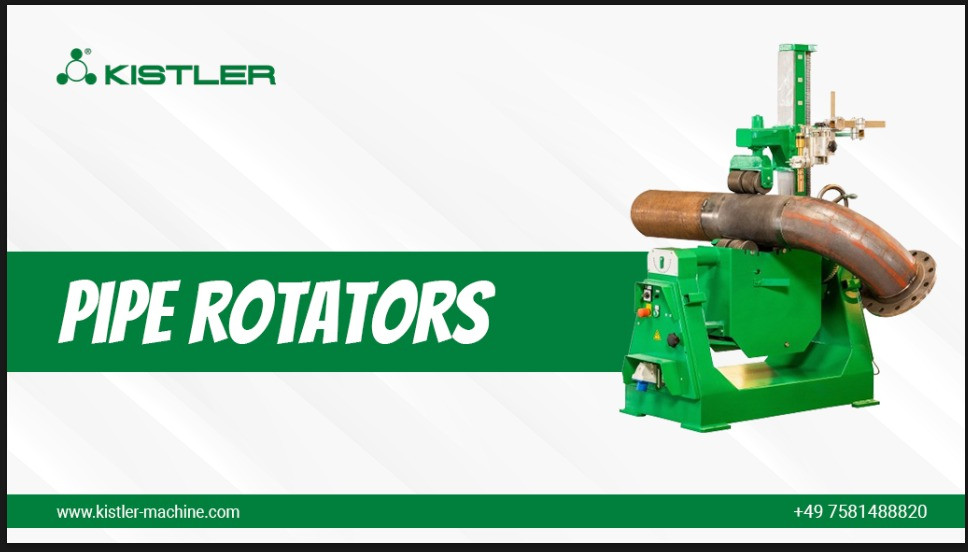

Pipe rotators are important for welding cylindrical and circular objects like tanks, pipes and pressure vessels.They are also known as pipe welding rotators.They play a crucial role in various industrial processes by making easy precise rotation of cylindrical workpieces during the process of welding. Pipe welders are designed for placement of conventional welding and fabrication of pipes and profiles.Pipe rotators are widely used in light and heavy fabrication that facilitate position and rotation of round objects.

The welding pipe rotators keep the pipes steady and rotate them in a cylindrical pattern. The heavy housings don’t require manual rotation by welders, thanks to the pipe rotators. As this allows the welder to focus more on the welding as he doesn’t have to rotate the pipe. Pipe welding rotators are used in manual and automatic welding for clamping , rotating and tilting of pipes with circular shape. These circular pipes are mostly used in the line of pipe construction for prefabrication and assembly on site and for central heating construction.

Types of pipe rotators

Pipe rotators are basically categorised into two major categories:

They are also known as manual pipe rotators. As the name suggests they need to be manually adjusted according to the size and circumference of the pipe. They consist of idle rollers. This is useful in welding jobs as they are used to rotate the pipes or the materials put on them.They are mostly used for cylindrical vessels.

In contrast to the conventional pipe rotators, the self-aligning pipes automatically adjust to the shape and size of the object, regardless of the ovality of the pipes. This characteristic feature is helpful for the welders. The self-aligning pipe rotators are incorporated with clutches which allows them to take more pounding than the conventional pipe rotators. This absence of clutches makes them prone to damage if handled roughly. Therefore, this makes the self-aligning pipes more reliable than the conventional pipe rotators.

The pipe rotators come with a number of salient features that helps them to achieve precise and efficient welding operations. They are as follows:

It assists in adjusting the rollers between the main body. This feature helps the user to adjust various rollers over the same roller. This helps in saving time and the cost as well as the user doesn’t have to buy a different size pipe roller for each diameter.

During the rolling phase the pipe surfaces can get scratched due to harsh surfaces. The polyurethane rollers offer a surface that won’t scratch the pipe surfaces. That makes your work done in less time and you don’t have to worry about the pies getting scratched.

If the polyurethane rollers are not secured properly on the frame, when a load is applied on them initially can cause damage to both the equipment and the operator. To ensure a safe working environment, the polyurethane rollers are secured with pins. This allows you to apply the maximum amount of weight that is estimated for your machine without worrying about the damage.

A non-adjustable stand can make the work difficult for the welders when they are working on the pipes. To avoid this inconvenience they are incorporated with adjustable stands that lets the welder adjust the height of the rigid stand as per their needs, thereby creating an overall better working experience.

A strong and sturdy base is necessary when putting a great load on the machine, in order to support the load. If the base of the machine is unable to support the load correctly, this can lead the machine to wobble or even tip over causing harm to the equipment and the operator. Hence a firm support is important to support the heavy loads that are estimated for the rotator. This creates a safe working environment for the operators.

Applications of pipe rotators

The pipe rotators offer a wide range of uses. Most of the industries where large and heavy cylindrical workpieces are required to be welded, these pipe rotators establish precise and smooth handling, which allows the welders to get high quality welds. The following are the applications of pepe welding rotators:

One of the major applications of pipe rotators is in the pipe manufacturing industries. They improve the welding process by uniform application of the weld seam and by maintaining the welding torch’s consistent distance and angle when it moves around the pipe. The high efficiency to deliver precision helps in higher production rates in reduced and decreased project timelines.

They are an integral part of the pressure vessels manufacturing industries as they improve the quality by providing precise and consistent placement of welds. Their adjustable and customizable features aid in different stages of pressure vessel construction.

Welding rotators are important tools in the fabrication of wind towers as they help in holding the heavy and large sections and rotating them so that the welders can join them together without the need of a crane or more operators. They also help in speeding up the welding process because the welders can place the parts fast and accurately.

They are crucial in the oil and gas industry and provide essential support in construction and maintenance of pipelines and storage tanks. They ensure uniform and steady welds, also allowing the welders a safe and controlled working environment. Uniform and strong welds are crucial in the oil and gas industry as the welds have to go through high pressure and harsh conditions.

Welding rotators speed up the construction process and also ensure consistent and high quality welds. Their adaptability feature plays a vital role in ship building because different vessel segments will require different welding tasks.

The pipe rotators play a central role in numerous industries by facilitating the accurate rotation of workpieces during the welding process. Kistler provides superior quality, state of the art pipe rotators which are extremely hard wearing as it is made from ultra high durable steel. Get in touch with Kistler today, to get the pipe rotators as per your needs to improve the productivity and efficiency of your businesses.